Development of high - gloss cardboard with double - zero aluminum foil production process£®2£©

2017/4/5 9:44:02

Roll grinding

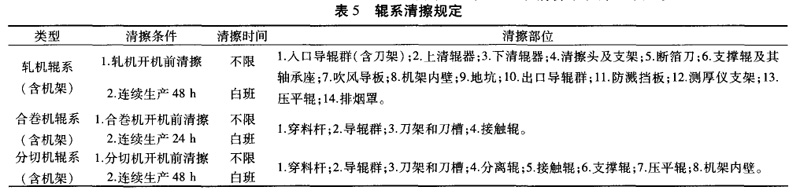

(1) The grinding scheme of the support roller is shown in Table 2.

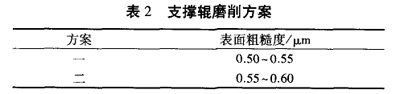

(2) the work roll after a period of time need to re-grinding the surface, the establishment of roll and surface roughness, the surface roughness of the need to determine the amount of road pressure reduction, aluminum foil surface quality requirements and rolling speed and other requirements of a comprehensive decision. Roller roughness is too high to improve the rolling speed at the same time to a certain extent due to the roller surface is too rough caused by aluminum foil surface oil film damage, while the rolling speed is too high will produce too much metal deformation heat, reduce oil film strength and lubricity , Resulting in oil film rupture. However, if the roll surface roughness is too low, resulting in excessive lubrication will roll on the aluminum foil surface slip, the formation of resonance pattern, a direct result of aluminum foil surface film break. Therefore, in each pass reasonable control roll roughness can improve the quality of aluminum foil surface. The grinding of the work roll is shown in Table 3.

Rolling oil control

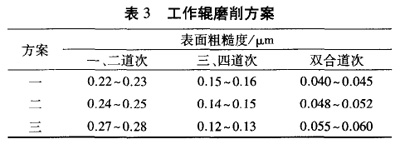

Rolling oil is the main role of the roll and rolling cooling and lubrication, and cleaning off the roll and strip surface due to the friction between the roll and the friction, wear aluminum powder. The composition, viscosity, temperature, cleanliness and the content of additives of the process lubricant have a great influence on the friction and wear in the rolling process. Therefore, the control of rolling oil index directly affects the surface quality of aluminum foil products, the additive ratio shown in Table 4.

The cleaning of the roller system during the production process

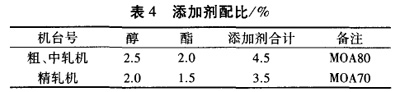

In order to ensure that the rolling and cutting process of aluminum foil surface cleaning and improve the gloss, reduce the finished pass off the line, developed a rolling mill, co-roll, slitting process roller cleaning requirements, see Table 5.